CO2 Live Line Cleaning

Electrical Utility Services

Clean Your Energized High Voltage Distribution Systems with CO2 Dry Ice Blast Cleaning

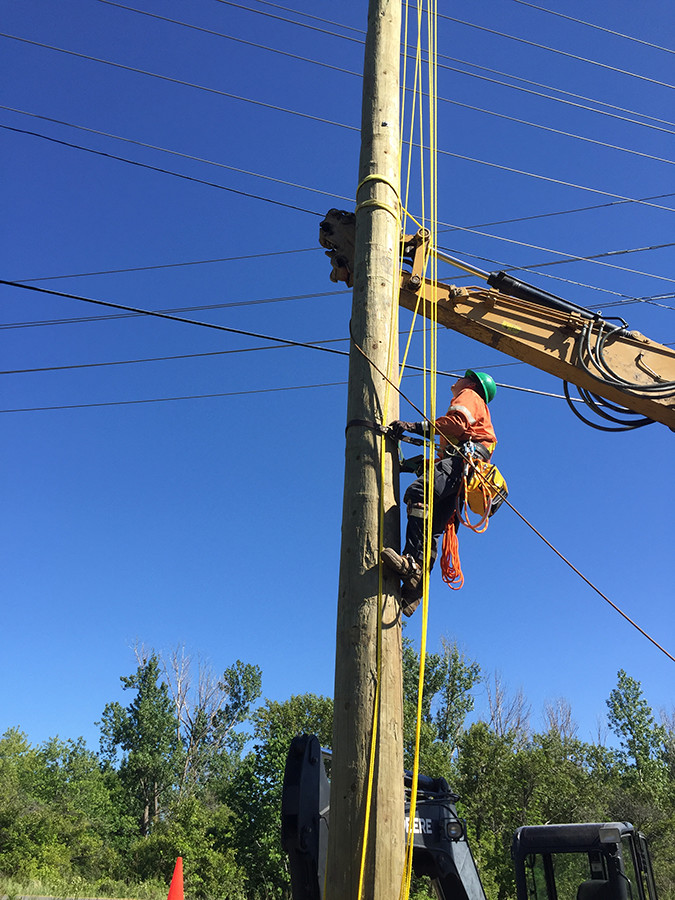

CO2 dry ice blast cleaning is a process that can be safely used on energized apparatus. It avoids costly switching procedures and the lost revenue associated with customer power outages.Our unique Live Line process has been applied to pad-mounted underground distribution equipment, operating at phase-to-phase voltages up to 28 kV. Cleaning applications include air insulated live-front switchgear cabinets, pad-mounted transformers, transformer rooms, and vaults.

Here’s What We Offer

We provide Live Line CO2 dry ice blast cleaning of high voltage equipment, detailed Visual inspection services including Thermographic IR imaging and Ultrasound tracking and arcing hot spot detection services. We supply a comprehensive Trouble Report that can be customized to suit your database. Utilizing certified licensed Power Lineman crews provides a high level of safety and electrical hazard awareness. And efficiency with our year-round, Canada-wide emergency and scheduled contract cleaning services.

Advantages of CO2 Dry Ice Blast Cleaning

You will not undergo interruption of service. Reduces power interruptions caused by flashovers. And there’s no pre-clean or clean-up because the dry ice disappears on contact. It’s a completely dry process–no drying time is required. There is no damage to your system components, and no lost revenue due to customer power outages. This process will improve system reliability and customer satisfaction. Benefit from this environmentally friendly process that doesn’t require utility manpower. Benefit from immediate cost-savings.

Contract Services

Wickens Industrial Contract CO2 Dry Ice Blast Cleaning:

An Efficient, Cost-effective and Environmentally Friendly Electrical Utility Cleaning Solution

With two fully equiped utility service vehicles, Wickens Industrial Live Line can quickly respond to the needs of our utility customers. Whether the need is 4 PMH switch gear or 200 we can handle your needs. We can average 5 units a day, 25 to 30 units a week to complete dry ice cleaning projects efficiently and on time.

- In addition we have a fully equiped inspection van to complete IR imaging, Ultrasound diagnostics, and proffesional visual inspections.

We are a service company, and we mean service.

Give us a call at 1-888-900-0086 or use our handy Contact form to enquire about your project.

Electrical Utility Services

Wickens Industrial has pioneered CO2 services to the Electrical Generation and Electrical Distribution Industries.

With two specialized fully equipped mobile vans Wickens Live Line has cleaned thousands of energized switch gear. We are proud to be a part of keeping electrical utilities up and running and supplying their customer base with reliable electrical energy.

Across the width and breadth of Canada, Wickens Industrial has supplied CO2 industrial cleaning services to Hydro, Thermal and Nuclear generating plants. Steam turbines, generator stators and rotors and nuclear decontaination have all benefited from the unique properties of CO2 dry ice blasting. Whether requiring contracted services or looking for the purchase of equipment, Wickens Industrial knows the industry and can supply what you want, where and when you need it.

Engineering & Design Services

Wickens has extensive experience with custom engineering projects.

To meet the demand for specialized equipment and services utilizing Cryogenic technology for use in the Electrical Utility Industry we have developed equipment and specifications to assure the high degree of safety required.

Two products resulting from these efforts are the highly efficient air preparation unit and modifications to the standard dry ice shaver to enable consistent operation with extended reach and under adverse conditions.

We have also designed and implemented one off proprietary equipment for our customers special needs and continue with several other projects.

Contact us at 1-888-900-0086

Cleaning of Electrical Generating Equip. Electrical Utility Services

CO2 Dry Ice Blast Cleaning of Electrical Generating Equipment

CO2 dry ice blast cleaning is an industrial cleaning process that can be applied to electric motors and generators effectively, safely and faster than other cleaning methods. We provide CO2 blast cleaning services and equipment to the electrical generating industry at hydro, nuclear and thermal stations.

Why Switch to CO2?

Switch to CO2 because it’s a completely dry process, leaving no concern for moisture introduction or drying time. Try this effective alternative to conventional grit or solvent cleaning. And remove years of contaminant build-up, carbon deposits, and even the remaining grit from previous cleaning methods. Eliminate the need for clean-up and reclamation costs associated with grit and solvents. There is no damage to stator slots, turbine blades, or delicate components such as winding insulation, older insulation coatings, and rotor pole surfaces. The impact of the dry ice particles reaches into the nooks and crannies not accessible by hand. Ultimately, this process provides the ability to turn jobs around more quickly, thus decreasing downtime. We offer reliable 24-hour response across Canada.

CO2 Blasting Technology FAQ

It is a process in which dry ice particles are propelled at high velocities to impact and clean a surface. The particles are accelerated by compressed air, just as with other blasting systems. Today, most applications are able to use standard shop air, in the 30 – 100 psi range.

In about 75% of the applications, users do not choose dry ice media based on its cleaning effectiveness because there is little or no difference. In the remaining cases, pellets work better in some of the applications, granules in others. Generally speaking, pellets are more effective with thick hard to remove contaminants as the greater mass behind each individual particle more readily travels all the way through the contaminant to disbond it. Because the granules are smaller than the pellets, they produce a significantly greater number of surface impacts and are therefore better at removing common contaminants found on switch gear and in transformer vaults.

Yes. It is easier to transport. Block dry ice has a longer shelf life. Pellets have a higher surface-to-mass ratio which makes them more hydroscopic, meaning they attract water. When stored, this causes them to sublimate (turn into a gas) faster than block. Block machines are larger and more complex and consequently are much more expensive to purchase and operate.

When you pull the trigger on the SDI-5, an actuator engages the ice, pushing it into the cutting face (the granulator) which produces particles that look much like raw sugar crystals, about 10 mils in size. Because the granulator only operates when the trigger is engaged. The SDI-5 is a patented system, the only blasting unit on the market capable of starting with block dry ice to create a blastable medium.

Pellets are made by taking liquid CO2 from a pressurized storage tank and dropping it to ambient pressure to produce snow. The snow is then pushed through a die to make pellets. The Triventek system is a mechanical extruder process in which the pellet extrudes through 3 easily interchangeable die plates.

It is made from liquid carbon dioxide. Dry ice exists as a liquid only under high pressure. When it drops to ambient pressure (the normal pressure that surrounds us), approximately half turns to gas and half turns to solid. The solid, usually in the form of fluffy snow, is then compressed to form dry ice blocks, pellets, or nuggets.

Once again, it depends on the mass of the object you’re blasting, your dry ice usage rate, and your dwell time. There will be condensation if you cool the substrate below the dewpoint (the dewpoint varies depending on local climate). Wickens Industrial has developed our air preparation unit to eliminate,as much as possible, condensation concerns. In addition we record the dew point before commencing cleaning operations in order to anticipate the production of condensation.

Yes, but generally not as much as you might think. The amount of cooling is dependent upon three main factors: mass of the targeted surface, dwell time, and ice usage rate. Generally cooling is not a concern and only rarely does it affect cleaning performance.

Generally no, but it depends on the substrate. There is an energy threshold at which disbonding will occur and a threshold at which damage will occur. When the disbonding threshold is lower than the damage threshold, you can clean. If the reverse is true, damage can occur. Adequate traing of the technician is required to assure that no damage occurs to the cabinet components.

People sometimes think it disappears too, but it does not. All cleaning involves the relocation of dirt. When you mop a floor, the dirt moves from the floor to the mop to the water in the bucket. With dry ice, the dirt moves from an undesirable area to an area where you can better deal with it. If it is a dry substance, it generally falls to the floor where it is swept away or vacuumed during normal maintenance. If it is a wet substance like grease, you take a methodical approach similar to hosing down a driveway. You start at one end and guide the grease to the other end where it is vacuumed or squeegeed up.

It sublimates and returns to the atmosphere as carbon dioxide (CO2) gas. CO2 is a naturally occurring element that constitutes less than 1% of our atmosphere.

Sandblasting is similar to using an ice pick whereas dry ice blasting is similar to using a spatula. Sand cuts or chisels away the contaminant. Dry ice lifts it away.

It depends on what you’re cleaning. If you’re removing a brittle contaminant such as paint, the process creates a compression tension wave between the coating and the substrate. This wave has enough energy to overcome the bonding strength and literally pop the coating off from the inside out. If you’re removing a malleable or viscous coating such as oil, grease, or wax, the cleaning action is a flushing process similar to high pressure water. When the particles hit, they compress and mushroom out, creating a high velocity snow flow that actually flushes the surface.

Dry ice blast cleaning originated at Lockheed in the 70’s when a coatings engineer, Calvin Fong, was researching ways to strip paint off aircraft. The technology did not become commercially available until Alpheus bought the license and patents from Lockheed and introduced it to the marketplace in 1987.

It is typical to operate at about 90 psi with 130 cfm, however your needs will depend on your application.

Our standard gun configuration is rated up to 200 psi which is well above the 80-100 psi generally used.

This is an important question to ask because the amount of dry ice needed to clean effectively can vary dramatically within from gear to gear. Generally we expect to use 1½-2 pounds per minute while the trigger is engaged. Of course, when you are cleaning, you won’t be pulling the trigger constantly. At a rate of 2 pounds per minute with 50% trigger time, you would use 60 pounds of dry ice in an hour.

Yes, the rate can easily be adjusted at the control panel on the SDI-5.

Since dry ice is -109°F, putting it in a freezer doesn’t really help. The best way to extend your shelf life is to store the ice in an insulated bin. Depending on the quality of the bin and how much ice you are storing, your loss due to sublimation should range from 2% to 10% per day.

Yes a properly designed and set up air preparation system is critical to safe energized electrical cleaning. Wickens Industrial has developed a system that exceeds the requirements to clean safely and effectively.

They are all tools in the toolbox. Consider that there are many types of hammers: ball peen; tack; claw; sledge; and so on. Could each do the job of the other? Perhaps, but the ideal toolbox would include each, because each has specific capabilities that it does better than any of the others. Electrical utilities have progressed through the use of all of these formats particularily in substation contamination problem areas the applicability of dry ice technology lends itself to voltages to 28 kv and light contaminants.

One issue is the temperature of the dry ice. At -109°F, we recommend you never handle it directly without gloves. Proper PPE for the contaminant involved is required and just as in sand blasting or steam cleaning, the gun should never be pointed at anyone or serious injury could occur. The issue that comes up most often is noise.

Yes. Noise is a function of air volume and air velocity. Within the nozzle, the stationary air is sheared by the high velocity air causing turbulence which creates noise. The level can range from 80 – 130 db. Hearing protection is required.

As long as it strikes the surface head on, dry ice does not ricochet because it sublimates (turns into a gas) on impact. As for the contaminant, you usually do not see or feel it as it disbonds and leaves the substrate, however, it is removed with some force which is why eye protection is recommended at all times.

Yes. Any dry air process will generate static electricity and dry ice blasting is no exception. In the Wickens Industrial system we have assured that both the blasting unit, vehicle and cabinet are properly grounded.

Replace it. The hoses carry high pressure air and could lead to problems if cracked or abraded.

Yes, with proper ventilation. Because CO2 is 40% heavier than air, placement of exhaust vents at or near ground level is recommended when blasting in an enclosed area. In an open shop environment, existing ventilation is sufficient to prevent undue CO2 buildup.